उत्पाद विवरण

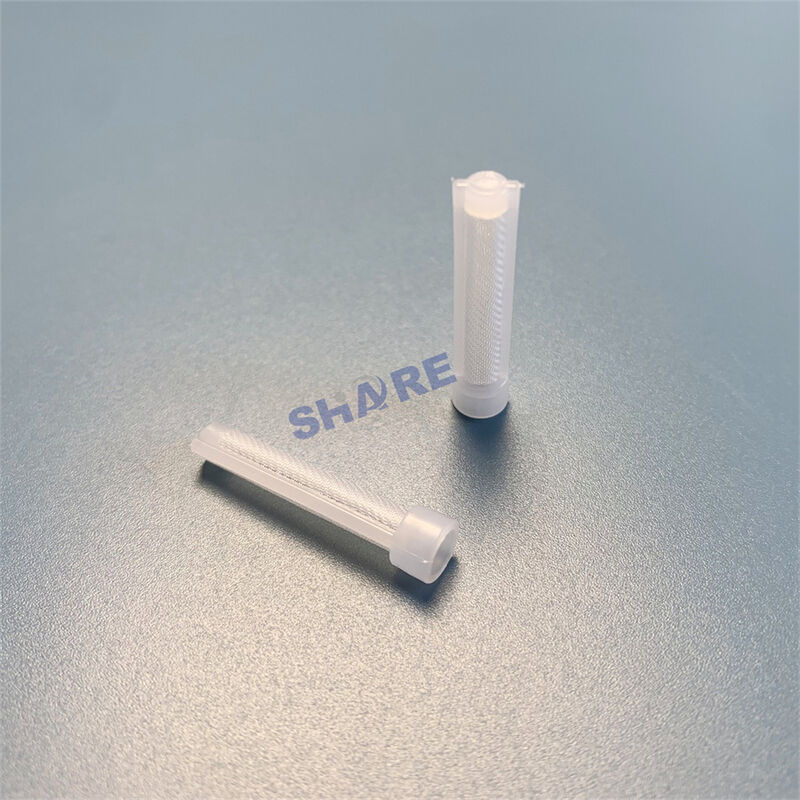

80 100 120 150 200 माइक्रोन पीपी मेश फ़िल्टर एसिड प्रतिरोधी रासायनिक घोल के साथ संगत

पीपी (पॉलीप्रोपाइलीन) मेश होने के लाभ हैंहल्का, मजबूत, रासायनिक रूप से प्रतिरोधी, लचीला और बायोकोम्पैटिबल, जो इसे सर्जिकल हर्निया/पेल्विक फ्लोर रिपेयर (सहायक ऊतक), निस्पंदन (आरओ/यूएफ सिस्टम), ऑटोमोटिव पार्ट्स और वस्त्रों के लिए आदर्श बनाता है, जो प्रदर्शन और लागत का एक अच्छा संतुलन प्रदान करता है, हालांकि यह अत्यधिक ठंड में भंगुर हो सकता है या एडिटिव्स के बिना मौसम प्रतिरोध की कमी हो सकती है। इसकी स्थिरता और ताकत ऊतक सुदृढीकरण के लिए टिकाऊ मचान प्रदान करती है, सर्जरी में पुनरावृत्ति को कम करती है, जबकि इसकी रासायनिक निष्क्रियता खाद्य संपर्क और औद्योगिक उपयोगों के लिए उपयुक्त है।

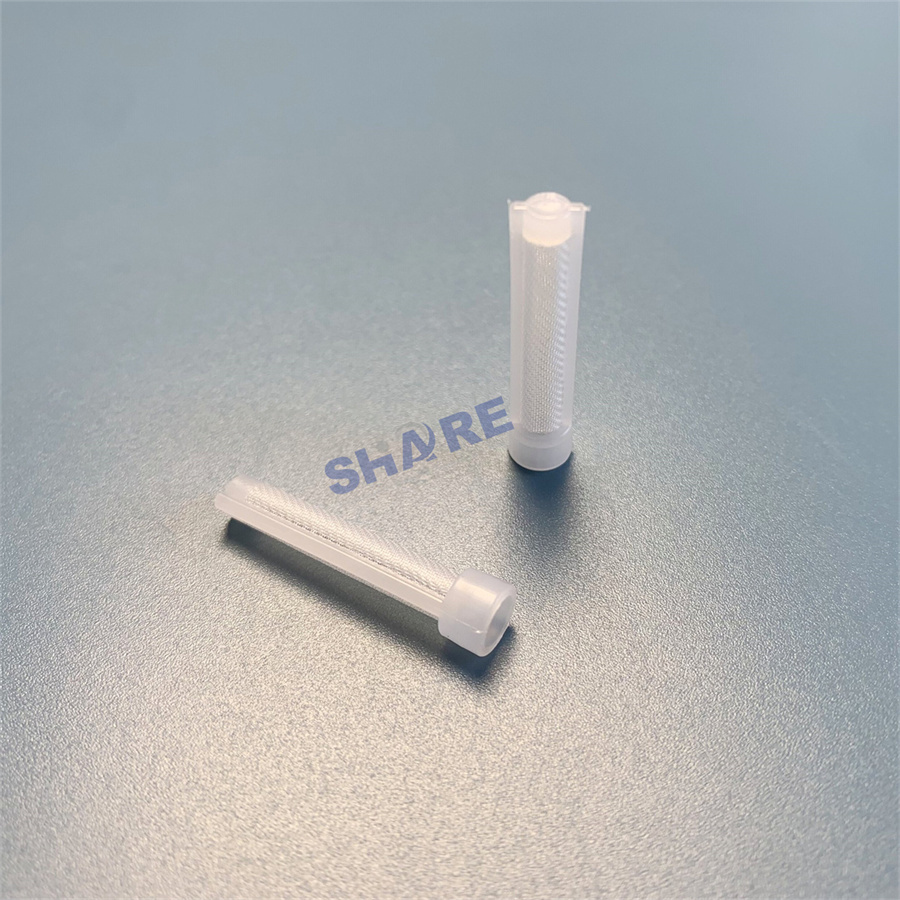

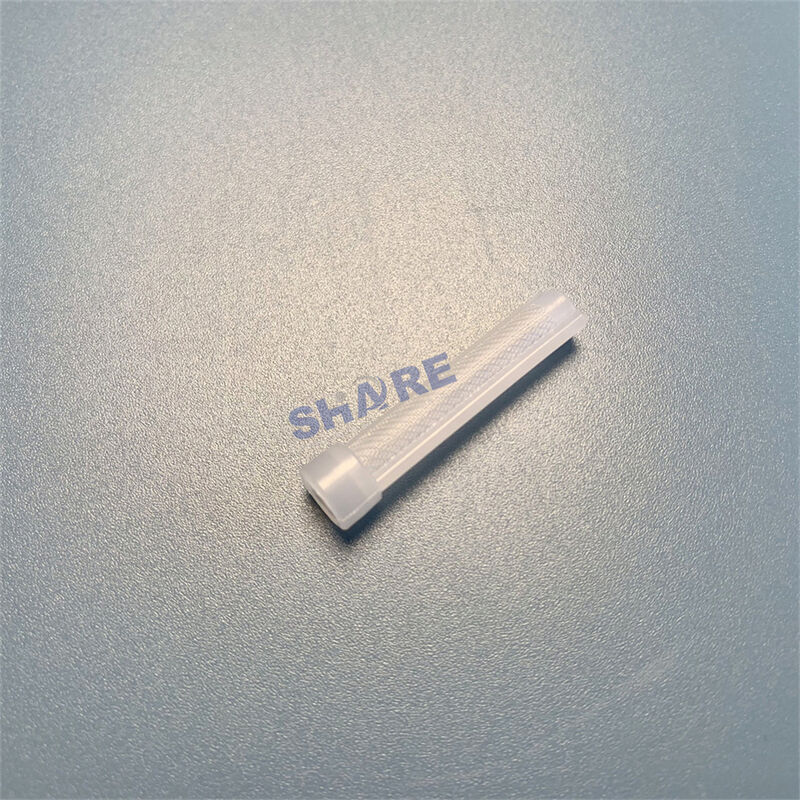

शेयर का पीपी ढालाफ़िल्टरएक पीपी फ़्रेम में रखे गए एक पीपी फ़िल्टर मेश से मिलकर बनता है, जो इसके उपयोग में अधिक विश्वसनीयता और दीर्घायु प्रदान करने वाले अधिक मजबूत भाग/उत्पाद की अनुमति देता है। इंजेक्शन मोल्डिंग कई रूप ले सकता है और शेयर फ़िल्टर इंजेक्शन मोल्डेड फ़िल्टर उत्पाद को विकसित करने और बनाने में पूरी तरह से सक्षम है जो आपकी आवश्यकताओं के लिए सबसे उपयुक्त होगा, साथ ही, रास्ते में कोई भी अतिरिक्त सलाह या सेवा प्रदान करेगा।

|

शेयरफ़िल्टर प्लास्टिक मोल्डेड का लाभफ़िल्टर

+फ़िल्टर माध्यम में नायलॉन मेश, पीईटी मेश, पीपी मेश, पीई मेश और एसएस मेश शामिल हैं।

+विकल्प के लिए मेश ओपनिंग की विस्तृत श्रृंखला, 3um से 1500um तक

+विभिन्न प्रकार केउपलब्ध फ़िल्टर और आकार

+सटीक और समान छिद्र आकार उच्च निस्पंदन दक्षता सुनिश्चित करते हैं

+फ़ैक्टरी सीधे आपूर्ति, लागत प्रभावी

+20 से अधिक वर्षों कासिंथेटिक फ़िल्टर मेश को प्लास्टिक के साथ एकीकृत करने का अनुभव

+स्थायित्व

+आसान स्थापना

|

|

मेश इंसर्ट प्लास्टिक मोल्ड फ़िल्टर सामग्री विकल्प

| सहायक फ्रेम सामग्री |

PA6, PA66, PET, PP, ABS, पीतल, और अन्य उच्च-प्रदर्शन थर्मोप्लास्टिक |

| फ़िल्टर मीडिया |

नायलॉन मेश, पॉलिएस्टर मेश, पीपी मेश, पीई मेश, धात्विक मेश |

| माइक्रोन रेटिंग |

3μm - 1500μm |

| मेश पार्ट्स फैब्रिकेशन |

लेजर कटिंग, सोनिक कटिंग, सोनिक वेल्डिंग |

| प्रक्रिया |

इंजेक्शन मोल्डिंग |

| आयाम |

कस्टम |

| रंग |

कस्टम |

उत्पाद की तस्वीरें

अनुकूलन

हम अनुरोध पर अपने उपलब्ध संस्करणों के बजाय अन्य रंगों या सामग्रियों का भी उपयोग कर सकते हैं.यदि फ़िल्टर के वांछित आयाम हमारी सीमा में शामिल नहीं हैं, तो हम आपकी विशिष्टताओं के अनुसार अनुकूलित कर सकते हैं। अधिक जानकारी के लिए हमसे संपर्क करें।

चीन से एक OEM मेश इंसर्ट मोल्डेड फ़िल्टर निर्माण

एक फ़िल्टर मेश और मोल्डेड फ़िल्टर निर्माण के रूप में, शेयर फ़िल्टर हमेशा अंतिम डिज़ाइन प्रिंट पूरे होने से पहले अपने OEM ग्राहकों के साथ उनके मेश निस्पंदन उत्पाद विकास परियोजनाओं पर सहयोग करने का सबसे अच्छा समाधान ढूंढते हैं। हमारे अनुभवी इंजीनियर न केवल आपकी कार्यात्मक आवश्यकताओं को पूरा करने में सक्षम हैं, बल्कि प्रदर्शन और निर्माण क्षमता में सुधार के लिए डिज़ाइन परिवर्तन की सिफारिश करने में भी सक्षम हैं। हम निम्नलिखित पर ध्यान केंद्रित करेंगे:

विचार क्षेत्र

शेयर फ़िल्टर दुनिया भर में हमारे ग्राहकों को उच्च गुणवत्ता वाले मेश फ़िल्टर घटकों को डिज़ाइन और बनाने में विशेषज्ञता प्रदान करते हैं। कस्टम-निर्मित डिज़ाइन के अनुसार फ़िल्टर मेश निर्माण और फ़िल्टर मेश प्रसंस्करण को संयोजित करने वाले एक आपूर्तिकर्ता के रूप में, हम अपने ग्राहकों की उत्पादन और डिलीवरी आवश्यकताओं के अनुकूल होने के लिए पर्याप्त लचीले हैं। हमारी उन्नत विनिर्माण प्रक्रियाएं और वैज्ञानिक मशीनें हमें किसी भी आकार या संरचना में निस्पंदन उत्पाद बनाने की अनुमति देती हैं - मेश टुकड़ों जैसे सरल घटकों से लेकर कस्टम संयोजन प्लास्टिक मोल्डेड फ़िल्टर जैसे जटिल उपकरणों तक। फ़िल्टर मेश रिबन, आकार, ट्यूब, बैग, इंजेक्शन-मोल्डेड फ़िल्टर और विभिन्न आकारों, आकारों और महीन मेश के समान उत्पाद हमारे प्राथमिक व्यवसाय हैं।

हम वह आपूर्तिकर्ता हैं जिसके पास सिंथेटिक फ़िल्टर मेश का अनुभव है और वे उन्हें अच्छी स्थिति में प्लास्टिक मोल्डिंग के साथ उपयोग करने में सक्षम हैं। मोल्डिंग तकनीक के लिए विशेष उपकरणों और सबसे बढ़कर बहुत अधिक जानकारी की आवश्यकता होती है।

हम स्वयं सीरियल इंजेक्शन मोल्डिंग टूल, असेंबली तैयारी और प्रक्रियाएं बनाते हैं। फ़िल्टर और पुर्जे निर्मित, असेंबल, गुणवत्ता नियंत्रित और पैक किए जाते हैं।फ़ैक्टरी क्षमताएं

शेयर फ़िल्टर विभिन्न में फ़िल्टर के निर्माण और पेशकश में विशेषज्ञ हैं

नायलॉन मेश सहित सामग्री पॉलिएस्टर मेश, पीपी मेश, धात्विक मेश, और हम इन फ़िल्टर को भी बदल सकते हैं मेश कोमेश रिबन, मेश आकार, डिस्क, मेश ट्यूब, फ़िल्टरबैग और मेश इंसर्ट प्लास्टिक मोल्डेड फ़िल्टरसीमा शुल्क की निस्पंदन मांगों को पूरा करने के लिए।शेयर फ़िल्टर सिंथेटिक मेश विभिन्न प्रकार की सामग्रियों जैसे पॉलीमाइड, पॉलिएस्टर, पॉलीप्रोपाइलीन आदि से बनाया जा सकता है। आप रोल द्वारा या कटे हुए आकार में ऑर्डर कर सकते हैं। स्लिटिंग का उपयोग मेश स्ट्रिप्स के निर्माण के लिए भी किया जाता है और किनारे पर बहुत कम सामग्री निर्माण के साथ एक बंद किनारा उत्पन्न करता है।

|

|

|

|

|

| हमारी कटिंग विधि में लेजर कटिंग, कोल्ड कटिंग, हीट कटिंग, पंचिंग शामिल हैं। कस्टम मेड टूल का उपयोग करके पेशेवर कटिंग जो सामग्री को नुकसान नहीं पहुंचाएगा। |

|

सोनिक कटिंग और वेल्डिंग सटीक, साफ हैं। रक्त निस्पंदन के लिए सटीक आस्तीन और बैग, रोसिन प्रेस के लिए रोसिन बैग उन अनुप्रयोगों के उदाहरण हैं जो इस तकनीक से लाभान्वित होते हैं। |

|

शेयर फ़िल्टर सिलाई उत्पादों को अत्यधिक कुशल और अनुभवी मशीनिस्ट द्वारा किया जाता है, जो यह सुनिश्चित करते हैं कि आपको सही स्तर की सुसंगत गुणवत्ता मिले। |

|

|

|

|

|

| कस्टम प्लास्टिक मोल्डेड फ़िल्टर सटीक फ़िल्टर मेश को बहुलक प्लास्टिक के साथ जोड़ते हैं। उद्योग सेवा: ऑटोमोटिव, उपकरण, खाद्य और पेय पदार्थ, चिकित्सा, जीवन विज्ञान और प्रयोगशाला। |

|

शेयरफ़िल्टर उत्पादों का अनुप्रयोग |

|

हमारे ग्राहक आधार में ऑटोमोटिव, घरेलू उपकरण, खाद्य और पेय पदार्थ, मिलिंग, चिकित्सा, जीवन विज्ञान और प्रयोगशाला, इलेक्ट्रॉनिकल के साथ-साथ अधिक सामान्य इंजीनियरिंग सहित विभिन्न प्रकार के उद्योग शामिल हैं, जो हमें कई क्षेत्रों में अनुभव का खजाना देते हैं। |

शेयर फ़िल्टर फ़िल्टर मेश संभावित अनुप्रयोगों के लिए कुछ जानकारी प्रदान करते हैं, लेकिन संभावित उपयोगों के व्यापक विवरण के लिए बहुत अधिक कार्य हैं। इसलिए, अपने विशेष उद्योग में संभावित अनुप्रयोग पर विचार करते समय, कृपया हमसे संपर्क करने पर विचार करें जो आपके विशिष्ट परियोजनाओं के लिए सही सामग्री और प्रसंस्करण चुनने में इंजीनियरों और उत्पाद डिजाइनरों के साथ काम करेंगे।

कृपया अभी हमसे जुड़ें ताकि हम आपके आवेदन और डिज़ाइन विशिष्टताओं के बारे में अधिक जान सकें!

यदि आपके पास निस्पंदन पूछताछ है तो कृपया हमसे संपर्क करें।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!